SAMSON Helical

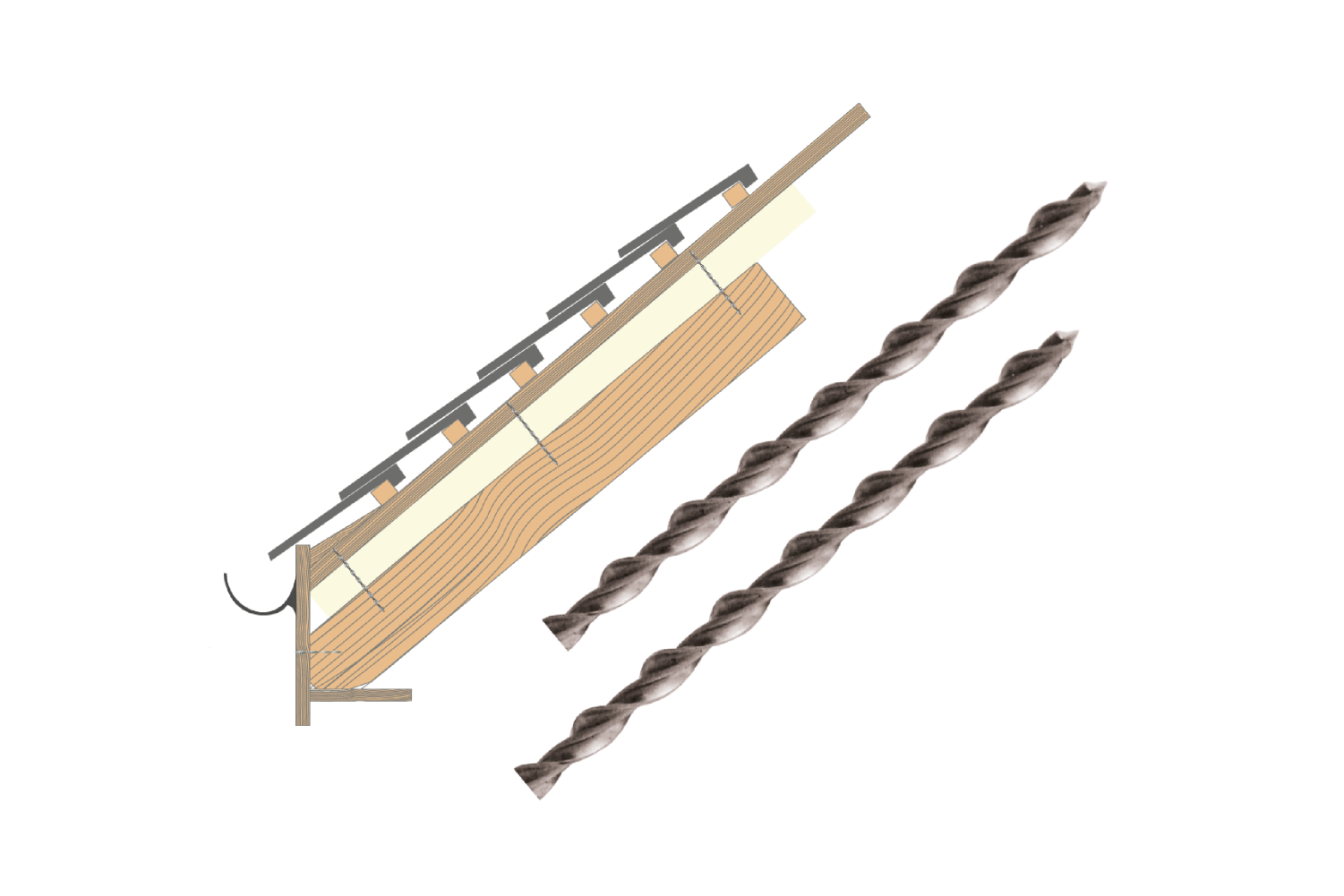

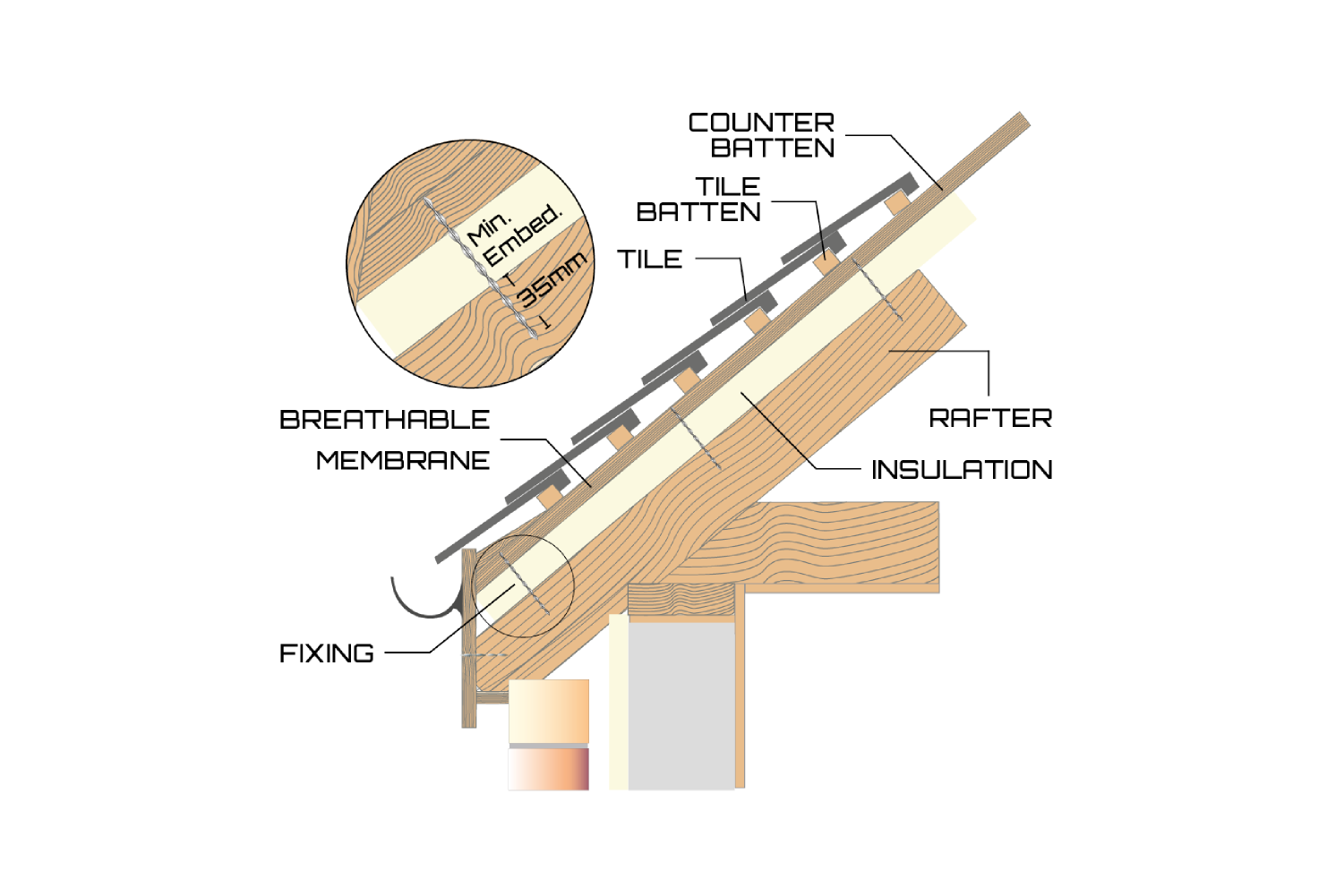

WARM ROOF FIXINGS

Downloads

Product Info

A Helical Fixing for Warm Roof Applications that is used to secure and sandwich a layer of insulation over the structural roofing timbers in energy efficient buildings.

ADVANTAGES

- Easy and fast installation

- Unlike a nail it rotates as it is driven in reducing the risk of splitting or bouncing timbers

- Does not compress insulation or impair thermal performance

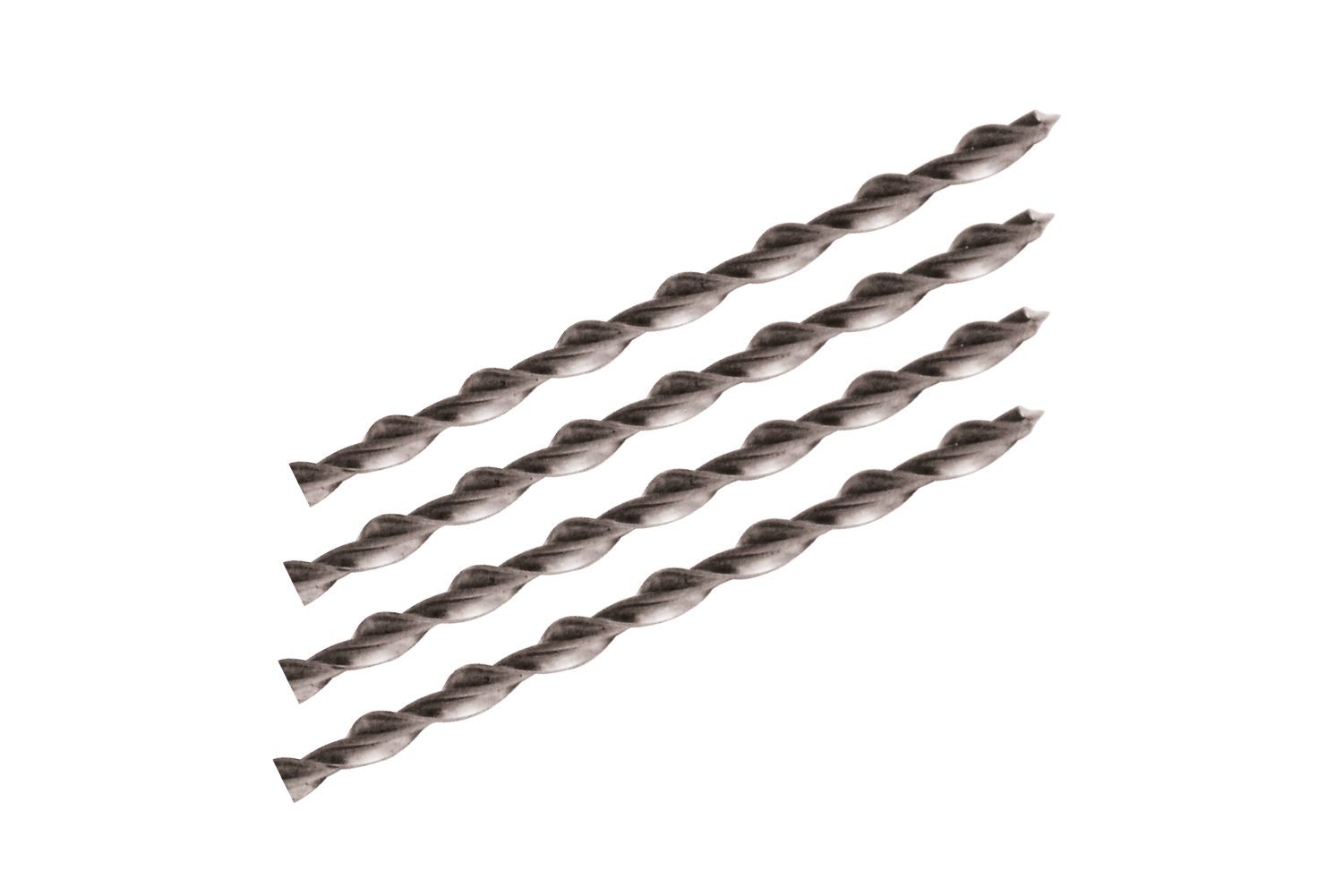

- Unique one-piece stainless steel fixing

- Excellent holding performance in tension and compression

- Supports heavy sliding loads in all wind conditions

- 6mm and HC7mm available

- 304 Stainless steel

- Hand hammered or power-driven without pre-drilling

- Headless for minimal thermal bridging

- Recommended by all the leading insulation manufacturers

- In house design service - Full technical data available

- Tested and endorsed by independent testing authorities

SAMSON HELICAL 1-POINT RANGE

- 6mm lengths available (mm): 100 • 110 • 120 • 125 • 130 • 135 • 140 • 145 • 150 • 160 • 170 • 180 • 190 • 200 • 205 • 210

- HC7mm lengths available (mm): 150 • 160 • 170 • 180 • 190 • 200 • 210 • 220 • 230

EN 10002-1:2001

EN 845-1:2003

EN 846-5:2000

EN 846-7:2000

EN 998-2-2004

MORE ADVANTAGES

- Roof timbers are kept warm and dry

- Creates a continuous thermal envelope without cold bridges, improving the thermal efficiency of the property

- Protects against damp and corrosion

- Roof tile ventilation is no longer required

- Produces warm usable space

- Capable of achieving Part L of building regulations

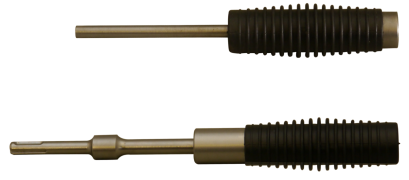

TOOLING

- We recommend tooling for 6mm fixings over 120mm long and for 7mm fixings over 170mm long

NOTE

If the thickness of the insulation exceeds 100mm or if the counter batten is warped an alignment installation tool is recommended enabling central alignment during installation.

MANUAL & HAND SUPPORT TOOL INSTALLATION

POWER SUPPORT TOOL INSTALLATION

INSTALLATION GUIDE

When fixing through hardwood we recommend that either a pilot hole is drilled or to install with a Power Installation Tool.

SAMSON HELICAL TIES can be driven using a conventional hammer. A series of light taps rather than heavy blows will allow the SAMSON HELICAL TIE to rotate during insertion. Hand- and Power Support Tools are also available.

- Line the counter batten up with the rafter beneath the insulation.

- Apply pressure to the counter batten pressing firmly onto the insulation.

- Place the SAMSON HELICAL TIE as near to the centre of the counter batten as possible and hammer home (Alternatively drive with Power Support Tool).

- Place the remaining fixings at the recommended spacings along the counter batten, and hammer home.

Once fixed at the recommended density the battens will feel vertically secure but may feel a little springy horizontally if the gap is not set tightly enough. This movement will be alleviated by the bracing effort of the tile battens which will provide additional lateral rigidity.

SAMSON HELICAL 1-POINT TIES can be driven using a conventional hammer. A series of light taps rather than heavy blows will allow the SAMSON HELICAL 1-POINT TIE to rotate during insertion. Alternatively you can use the SDS Power support tool to drive the fixings home.

- Line the counterbatten up with the rafter beneath the insulation.

- Apply pressure to the counterbatten pressin firmly onto the insulation.

- Place the SAMSON HELICAL 1-POINT TIE as near to the centre of the counterbatten as possible and hammer home (Alternatively drive with Power Support Tool).

- Place the remaining fixings at the recommended spacings along the counterbatten, and hammer home.

Once fixed at the recommended density the battens will feel vertically secure, but may feel a little springy horizontally if the gap is not set tightly enough. This movement will be alleviated by the bracing effort of the tile battens which will provide additional lateral rigidity.

At SAMSON we realize that safety and performance are paramount in the structural repair and fixing markets. To guarantee the products safety, tension is induced through the SAMSON HELICAL section by the twisting motion in the manufacturing process. This ensures that all impurities in the base material are detected early, and any inferior materials discarded.

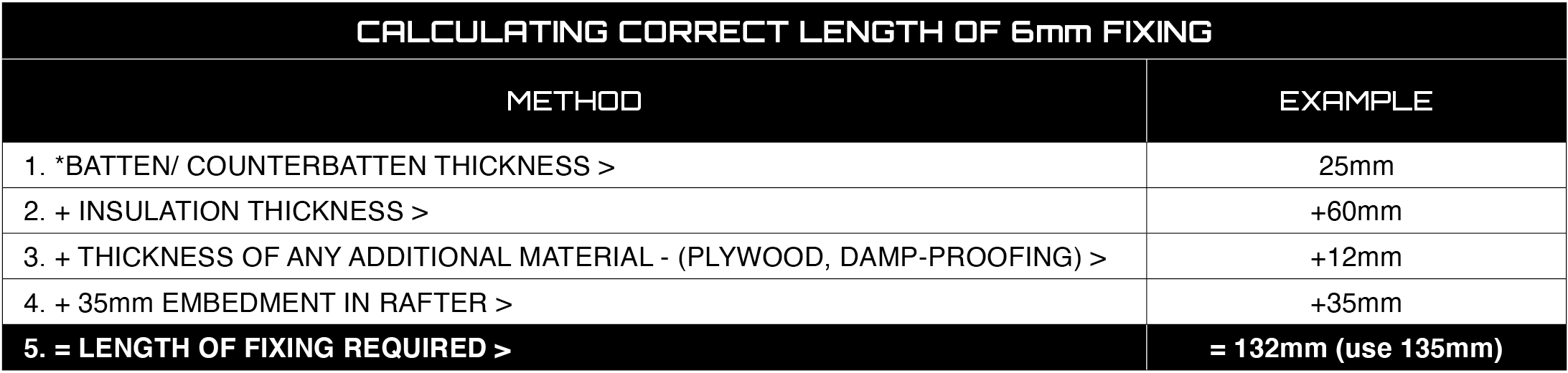

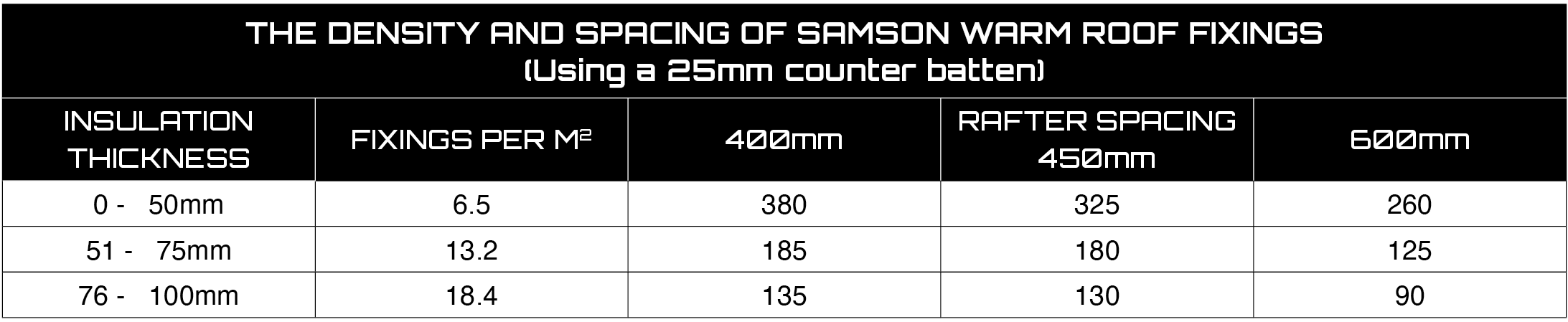

CALCULATING THE QUANTITY OF FIXINGS

Batten fixings per m² x Total roof area m² = Quantity required

*25mm minimum counter batten thickness 38mm

Recommended by BRE

Insulation is getting much thicker to help to conform to part L of the building regulations, thus helping to reduce carbon emmisons. SAMSON HELICAL now has a HC7mm ø fixing to improve the efficiency of fixing insulation over 50mm thick.

The table has been designed to suit the majority of applications. It is suitable for projects matching all of the following criteria:

- Buildings up to 15 metres in height

- Roof coverings up to 60kg/m²

- Minimum counter batten thickness of 25mm

- Using a 38mm counter batten will reduce the quantity of fixings required per M2 *

- Slope of ground within 1km up to 1:12.5

- Locations in wind zones up to 52m/s

*Contact the SAMSON Technical Department for assistance.

At SAMSON we realize that safety and performance are paramount in the structural repair and fixing markets. To guarantee the products safety, tension is induced through the SAMSON HELICAL section by the twisting motion in the manufacturing process. This ensures that all impurities in the base material are detected early, and any inferior materials discarded.